Modle | Screen Spec (㎡) | Lnstallation slope(°) | Double amplitude(mm) | Maximum feed size(mm) | Capacity (t/h) | Vibrating frequency(r/min) | Motor power(kw) | Overall dimension(mm) | Weight (kg) | Remark |

GZZ0725 | 1.875 | 0-10 | 9-11 | ≤200 | 200-220 | 670 | 11 | 2568*1959*1090 | 2550 | Without grid section |

GZZ0936 | 3.2 | 0-10 | 9-11 | ≤200 | 200-220 | 800 | 18.5 | 3740*2075*1361 | 4200 | With grid section |

GZZ1248 | 5.4 | 0-10 | 9-11 | ≤300 | 250-280 | 800 | 22 | 4958*2350*2290 | 5900 | With grid section |

GZZ1548 | 6.86 | 0-10 | 9-11 | ≤300 | 320-350 | 800 | 22 | 4958*2750*2390 | 7100 | With grid section |

GZZ1660 | 10.29 | 0-10 | 9-11 | ≤300 | 350-380 | 800 | 22 | 6400*1670*1526 | 7300 | Without grid section |

GZZ1848 | 8.44 | 0-10 | 9-11 | ≤300 | 380-410 | 800 | 22 | 4958*3100*2490 | 8500 | With grid section |

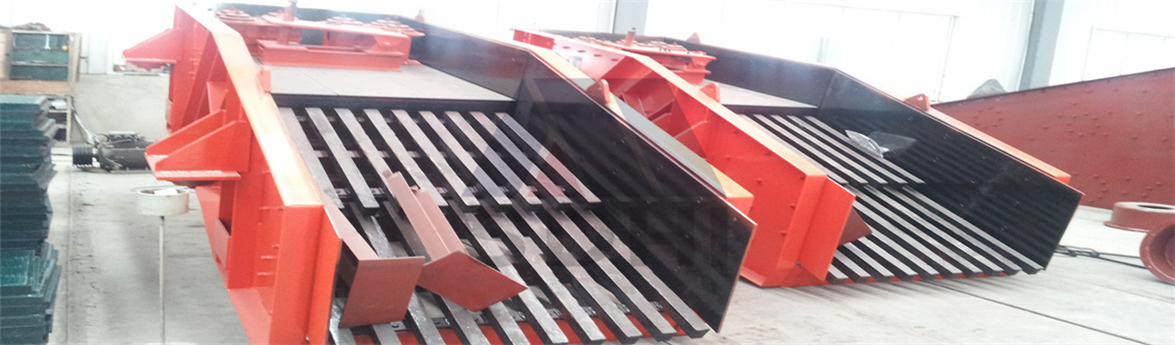

The advantages of GZZ Vibrating Feeder:

Structure strong, impact resistance, wear resistance

Stable vibration, reliable operation, long life; the excitation force can be adjusted, and the flow can be changed and controled at any time conveniently and stably

Low noise, low power consumption, good regulation performance, no punch phenomenon.

Simple structure, reliable operation, easy adjustment and installation, light weight, small volume, convenient maintenance. It can prevent dust pollution when using a closed structure.

The device adopts a controllable silicon half wave rectifying circuit. Adjusting the feeding quantity is convenient by adjusting the opening angle of the controllable silicon, and it can realize the centralized control and automatic control of the production process.

Special feeder grid design can prevent the blockage of materials

Grid gap can be adjusted

Many parts are wear parts

The Production cycle of Shunda GZT Vibrating Feeder is about 65 days, but it is only for reference. Due to the impact of climate, the supply and demand of raw materials and other factors, there will be little changes in the specific production cycle, the details please get in touch with Shunda staff and subjected to the contract.

GZZ Series Vibrating Feeders is a new product which is developed by the introduction of latest foreign technology. Feeding face has two forms of the blind plate and bars and whole blind plate. The former is mainly appliedto large materials` evenly feeding before the crusher and the latter can feed the affected device continuously or periodically. If accompanied by electronic scales, GZZ can realize automation in dosing, packaging and other production processes. It is widely used in mining, metallurgy, coal, building materials, light industry,electricity, chemicals, food and other industries.