GBZ Heavy Board Style Feeding Engine Product Introduction

Model | Width (mm) | Sprocket center distance( mm) | Speed (m/s) | Feed grain size (mm) | Production capacity(m³/h) | Installation angle | Electric motor | Overall dimensions(mm) | |

Model | Power(kw) | ||||||||

GBZ120-4.5 | 1200 | 4500 | 0.015-0.048 | ≤500 | 100 | 0-25° | YCT250-4A | 22 | 7133*5293*2079 |

GBZ120-6 | 1200 | 6000 | ≤500 | 100 | YCT250-4A | 22 | 8683*5293*2079 | ||

GBZ150-6 | 1200 | 6000 | ≤600 | 150 | YCT280-4A | 22 | 8633*5593*2079 | ||

GBZ150-7 | 1500 | 6000 | ≤600 | 150 | YCT280-4A | 22 | 9683*5593*2079 | ||

GBZ150-8 | 1500 | 8000 | ≤600 | 150 | YCT280-4A | 22 | 10533*5593*2079 | ||

GBZ180-8 | 1800 | 8000 | ≤800 | 240 | MDSP225S-4 | 37 | 10533*6305*2079 | ||

GBZ180-10 | 1800 | 10000 | ≤800 | 240 | YCT315-4B | 45 | 12533*63005*2079 | ||

GBZ220-12 | 2200 | 12000 | ≤1000 | 360 | YCT315-4B | 45 | 14478*7321*2079 | ||

GBZ240-5.6 | 2400 | 5600 | ≤1000 | 400 | MDSP225S-4 | 37 | 8133*6718*2079 | ||

GBZ240-10 | 2400 | 10000 | ≤1000 | 400 | YCT315-4B | 45 | 12533*6736*2079 | ||

The above data is only for reference. The acctual capacity will depend on the production condition and the crushing material type.

GBX Heavy Board Style Feeding Engine Product Introduction

Model | Width (mm) | Sprocket center distance(mm) | Speed (m/s) | Feed grain size (mm) | Production capacity (m³/h) | Speed reducer | Electric motor | Overall dimensions (mm) | ||

| structure | Velocity ratio | Modle | Power (kw) | |||||||

GBX1250*4500 | 1250 | 4500 | 0.075-0.126 | ≤600 | 100-350 | Planetary and orthogonal | 389 | MDSP180L-4 | 22 | 7070*3950*2260 |

GBX1500*4000 | 1500 | 4000 | 0.04-0.08 | ≤700 | 200-500 | 440 | MDSP250M-6 | 37 | 7340*4249*2480 | |

GBX1250*6000 | 1250 | 6000 | 0.075-0.125 | ≤600 | 100-350 | 389 | MDSP180L-4 | 22 | 8570*3950*2260 | |

GBX1600*6000 | 1600 | 6000 | 0.04-0.08 | ≤750 | 300-600 | 440 | MDSP250M-6 | 37 | 9138*4349*2580 | |

GBX1800*8000 | 1800 | 8000 | 0.06-0.1 | ≤800 | 500-900 | 490 | MDSP225M-4 | 45 | 11832*4249*2830 | |

GBX2000*6000 | 2000 | 6000 | 0.075-0.125 | ≤950 | 850-1450 | 389 | MDSP250M-4 | 55 | 9478*4794*2980 | |

GBX1500*8000 | 1500 | 8000 | 0.04-0.08 | ≤700 | 200-500 | 440 | MDSP250M-6 | 37 | 10932*4249*2480 | |

GBX2000*8000 | 2000 | 8000 | 0.075-0.125 | ≤950 | 850-1450 | 389 | MDSP250M-4 | 55 | 11138*4794*2980 | |

GBX1800*10000 | 1800 | 10000 | 0.06-0.1 | ≤850 | 500-900 | 490 | MDSP225M-4 | 45 | 13138*4594*2780 | |

GBX1500*10000 | 1500 | 10000 | 0.04-0.08 | ≤950 | 200-500 | 440 | MDSP250M-6 | 37 | 12984*4294*2480 | |

The advantages of Board Style Feeding Engine:

Double circular arc plate is used to prevent the leakage.

The traction chain uses the bearing and traction separate structures, which improves the ability to withstand impact load plate feeder

The tail tensioning device is provided with a disc spring, which can slow down the chain impact load and improve the service life of the chain.

Large traction power, small power consumption, low wear and tear, less leakage, stable operation, reliable operation, long service life, easy maintenance

Adaptable, adjustable conveying capacity and continuous uniform delivery of various materials

Most of the no-load start, no overload, accident with rated load start-up, a maximum of 70t coal in the hopper

Plate feeder adopts two point support, one end directly places on the crusher. The layout is simple, which saves construction cost

Plate feeder tail device adopts special design, suitable for rainy and humid area, never has the chain teeth jump phenomenon because of sticky material accumulating on the tail, thus affecting the production

There is sleeper shock absorption on the tail of plate feeder. The middle has a number of special shock absorbing roller bearing, improving the bulk material impact on both sides of the roller and groove plate stress conditions, and the service life of running parts

Head device sprocket has 13-15 teeth. Odd and even teeth separate to transmit, so life can be doubled

The head gear sprocket is cut into 3 lobe teeth, without the need to remove the chain plate to replace the teeth, easy maintenance

The Production cycle of Shunda Board Style Feeding Engine is about 65 days, but it is only for reference. Due to the impact of climate, the supply and demand of raw materials and other factors, there will be little changes in the specific production cycle, the details please get in touch with Shunda staff and subjected to the contract.

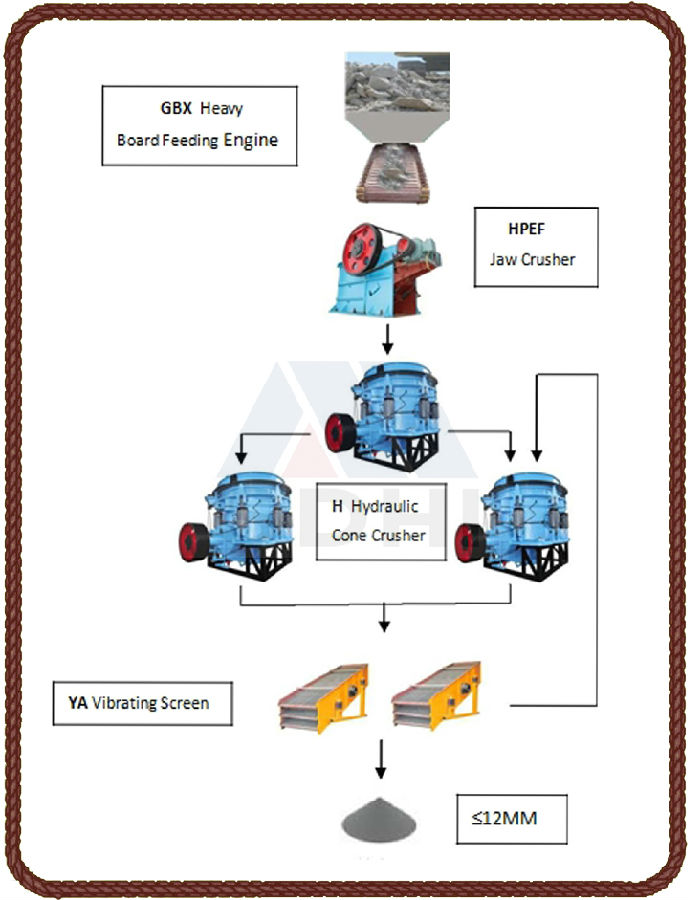

As a kind of fixed feeding machinery, plate feeder is auxiliary equipment for crushing process and feeds materials continuously and uniformly to primary breaker through feed bin while being available for short-range material handling. Plate feeder is particularly useful for conveyance of materials with large specific gravity, relatively large grain size and strong abradability and can operate reliably under extreme conditions such as open environment and damp environment etc. Having been widely used in industries of metallurgy, mine, cement and building material etc. Plate feeder could be either horizontally mounted or be installed in an inclined in and inclined manner an a maximum inclination angle of 25º.

We can produce plate feeders of various specifications and models including heavy, medium, light-duty and new-style (OK board) plate feeders. Compared with old-style heavy duty feeding machine, the new-style feeding machine features more rational overall structure and convenient installation, disassembly and maintenance.

Drive unit incorporates integrated hanging and single-point folating structure that could reduce mounting error and prolong the service life of transmission system.

Depending on requirements of different users, drive unit combinations include planetary orthogonal reducer combination, Flender orthogonal reducer combination and cycloidal planetary gear combination. Caterpillar chain (or self-fabricated chain) is used as driving chain of scraping belt device. Scraping belt employs two lapping methods, i.e. singe circle and double arc, both of which feature resistance to impact, wear and material leakage. The overall equipment incorporates keyless joint that contributes to compact structure, convenient mounting and removal and outstanding chain synchronization.

![]() Board Style Feeding Engine.pdf

Board Style Feeding Engine.pdf