Modle | Cylinder diameter(mm) | Cylinder length(mm) | Effective volume(m³) | Maximum ball charge(t) | Operating rotation speed(r/min) | Motor power(kw) |

MQS2122 | 2100 | 2200 | 6.6 | 15 | 23.8 | 155 |

MQS2130 | 2100 | 3000 | 9 | 20 | 23.8 | 210 |

MQS2136 | 2100 | 3600 | 10.8 | 22 | 23.8 | 210 |

MQS2140 | 2100 | 4000 | 12 | 24 | 23.8 | 245 |

MQS2145 | 2100 | 4500 | 13.5 | 27 | 23.8 | 245 |

MQS2430 | 2400 | 3000 | 11.7 | 22.5 | 22.7 | 280 |

MQS2436 | 2400 | 3600 | 14 | 26 | 22.7 | 315 |

MQS2442 | 2400 | 4200 | 16.3 | 30 | 22.7 | 355 |

MQS2721 | 2700 | 2100 | 10.8 | 23 | 21.7 | 260 |

MQS2727 | 2700 | 2700 | 13.9 | 29 | 21.7 | 310 |

MQS2736 | 2700 | 3600 | 18.5 | 39 | 21.7 | 400 |

MQS2740 | 2700 | 4000 | 20.6 | 42.5 | 21.7 | 440 |

MQS2745 | 2700 | 4500 | 22.1 | 46 | 21.7 | 500 |

MQS2750 | 2700 | 5000 | 25.7 | 51 | 21.7 | 630 |

MQS2760 | 2700 | 6000 | 30.8 | 64 | 21.7 | 800 |

MQS3040 | 3000 | 4000 | 25.5 | 48 | 19.5 | 630 |

MQS3045 | 3000 | 4500 | 29 | 53 | 19.5 | 630 |

MQS3230 | 3200 | 3000 | 21.3 | 46 | 18.6 | 500 |

MQS3236 | 3200 | 3600 | 25 | 58 | 18.6 | 630 |

MQS3245 | 3200 | 4500 | 32.8 | 65 | 18.6 | 800 |

MQS3260 | 3200 | 6000 | 43.7 | 90 | 18.6 | 1000 |

MQS3639 | 3600 | 3900 | 36 | 75 | 17.8 | 1000 |

MQS3645 | 3600 | 4500 | 41 | 90 | 17.8 | 1250 |

MQS3650 | 3600 | 5000 | 46.2 | 96 | 17.8 | 1400 |

MQS3660 | 3600 | 6000 | 57 | 120 | 17.8 | 1600 |

MQS4060 | 4000 | 6000 | 69.8 | 137 | 16 | 1700 |

MQS4270 | 4200 | 7000 | 89 | 176 | 15.7 | 2200 |

MQS4560 | 4500 | 6000 | 87 | 158 | 15.1 | 2300 |

MQS4866 | 4800 | 6600 | 107.5 | 200 | 15 | 3000 |

MQS5592 | 5500 | 9200 | 202 | 375 | 13.7 | 5200 |

The advantages of MQS Wet Grate Discharge Ball Mill:

Fine grinding granularity, wide range of products

The failure of the production has reduced: wet ball mill is a low arrangement, the barrier because of the height in the past has been alleviated.

Production more convenient: do not often on the escalator when we operate on a wet ball mill

Simple structure, low investment costs

There are grid plates and a pulp lifting device at the outlet end cover of grate discharge ball mill, which forces discharge and increases production

Liquid level of energy-saving grate discharge ball mill is low, can well discharge qualified mineral particles, and avoid excessive crush.

Because of the liquid level is low, the resistance of the balls is little,and the crushing effect is good

Great discharge ball mill`s load of ball is huge, the quantity of balls can be placed according to the grinding effect.

The Production cycle of Shunda MQS Wet Grate Discharge Ball Mill is about 70 days, but it is only for reference. Due to the impact of climate, the supply and demand of raw materials and other factors, there will be little changes in the specific production cycle, the details please get in touch with Shunda staff and subjected to the contract.

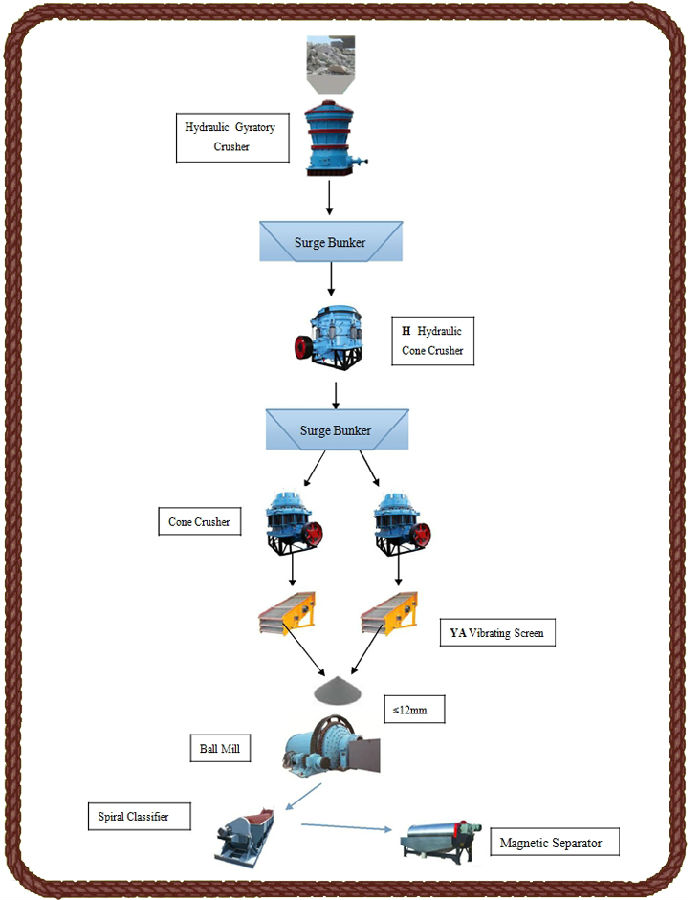

The ball grinder is a kind of equipment to grind ores and other materials with powder to obtain desirable granularity of products. The ball grinder designed and manufactured by our company has been widely applied in such industries as metallurgy, mining, building materials and chemical industry home and abroad.

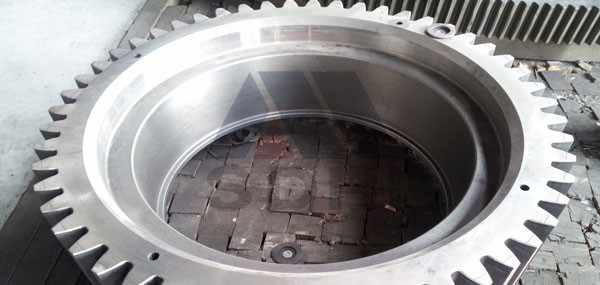

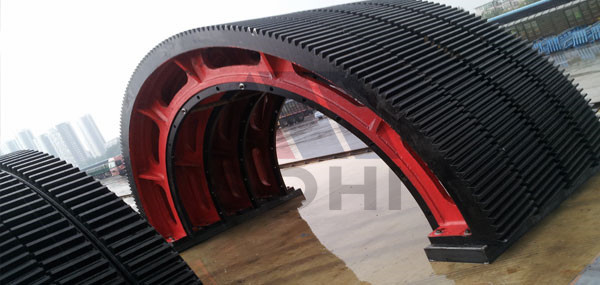

The ball grinder is mainly composed of feeding, charging, main bearing, barrel, transmission, discharging parts and main motor. The barrel of grinder is driven by the motor through transmission and deceleration of gear pair to rotate in appropriate rotary speed. The medium for ore grinding is lifted to a definite height under the action of centrifugal force, friction and gravity and then drop down in throwing up or falling state. The materials within barrel are crushed under impact of medium.

Meanwhile, the materials are ground under grinding stripping action due to rolling or sliding of medium. The materials are discharged through discharge hole after being ground. The grinder may be provided with air clutch, slow driving/jacking/jet lubrication devices as required. The ordinary sliding bearing, dynamic/static pressure bearing, hydrostatic bearing and rolling bearing may be adopted for main bearing of grinder as required.

The rolling bearing can be adopted for main bearing of ball grinder below Φ6200 (includingΦ6200) series manufactured by our company, which is characterized by simple structure, high efficiency as well as easy installation and maintenance.

The magnetic lining plate may be adopted for ball grinder as required, which is thinner compared with the metal one, lighter in weight and longer in life. It can reduce the energy consumption while improving output and is applicable for two-section grinder generally. Our company is able to design and manufacture the grinder with various specifications for multiple uses based on customer demands.

![]() MQS Wet Grate Discharge Ball Mill.pdf

MQS Wet Grate Discharge Ball Mill.pdf