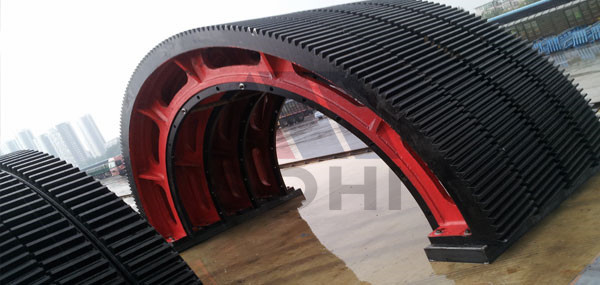

transmission gear/big gear of MQS Wet Grate Discharge Ball Mill

Material: Gear material has enough strength, high wear resistance and good machining performance. The ring gear material commonly used ZG270~500 ZG310~570, but in front of the processing must be normalizing treatment, the hardness is reduced to HB170~200. 35SiMn, 45MnB, 40Cr and other materials, the small gear, after quenching and tempering treatment, the hardness of up to HB220~250. Development direction is to use high strength alloy steel instead of the above materials. Such as the small gear and a small gear shaft with CrNiMo steel quenched and tempered, the maximum strength after quenching and tempering for 1150MPa, and ring gear 42CrMo quenched and tempered steel, the strength after quenching and tempering for 900MPa

Technics: Edge transmission gear ring shaped body, usually consists of two ring gear combination, so it is easy to disassembly. The tooth number is even, and the two halves of the ring are in the right order.

Rapid wear: Yes

Quality assurance: 18 months

Production Poried: 70 days