Model | Bottom size of breakingcone | Size of feed Port (mm) | Maximum size of feed Port(mm) | Discharge outlet adjustment range | Production capacity(t/h) | Main motor power(kw) | Number of spring sets | Total pressure of spring/single-set pressure (KN) |

PYT-B0913 | 900 | 135 | 115 | 15-50 | 50-90 | 75 | 10 | 700/70 |

PYT-Z0907 | 900 | 70 | 60 | 5-20 | 20-65 | 75 | 10 | 700/70 |

PYT-D0905 | 9900 | 50 | 40 | 3-13 | 15-50 | 75 | 10 | 700/70 |

PYT-B1217 | 1200 | 170 | 145 | 20-50 | 110-168 | 110/130 | 10 | 1500/150 |

PYT-Z1211 | 1200 | 115 | 100 | 8-25 | 42-135 | 110/130 | 10 | 1500/150 |

PYT-D1206 | 1200 | 60 | 50 | 3-15 | 18-105 | 110/130 | 10 | 1500/150 |

PYT-B1725 | 1750 | 250 | 215 | 25-60 | 280-480 | 155/180 | 12 | 3000/250 |

PYT-Z1721 | 1750 | 215 | 185 | 10-30 | 120-350 | 155/180 | 12 | 3000/250 |

PYT-D1710 | 1750 | 100 | 85 | 5-15 | 75-230 | 155/180 | 12 | 3000/250 |

PYT-B2235 | 2200 | 350 | 300 | 30-60 | 590-1000 | 280/330 | 16 | 4000/250 |

PYT-Z2227 | 2200 | 275 | 230 | 10-30 | 300-580 | 280/330 | 16 | 4000/250 |

PYT-D2213 | 2200 | 130 | 100 | 5-15 | 125-350 | 280/330 | 16 | 4000/250 |

The advantages of Spring Cone Crusher Series:

Optimization of cavity design, reasonable combination of speed and stroke, so that the models under the condition in the same dynamic cone diameter do the most work, so it has higher performance and production capacity.

Laminated crushing principle to increase the proportion of the cube in the product, the needle sheet stones reduced, more uniform particle size

When iron and other non broken material goes into the machine, iron protection device will automatically release, then under the function of the spring, the device automatic resets.

Spring cone crusher can enable the crusher to maximize performance and is applicable to various crushing process: from coarse to fine crushing, from fixed to mobile crusher station. There are also a variety of cavity can be selected.

Independent oil lubrication system to ensure that the double protection of the models of bearing lubrication, and realize the automatic safety protection

The Production cycle of Shunda Spring Cone Crusher is about 65 days, but it is only for reference. Due to the impact of climate, the supply and demand of raw materials and other factors, there will be little changes in the specific production cycle, the details please get in touch with Shunda staff and subjected to the contract.

It is the main equipment used for medium and fine crushing of ores or rocks with different hardness in such industries as metallurgy, chemical industry, building materials, water and electricity and road paving, which is characterized by reliable structure, stable running, high production efficiency, convenient adjustment and uniform granularity of products.

Our company has a history for manufacturing as long as almost 20 years, the cone crushers are main products of our company. Such four specifications are available for ordinary cone crushers as 900, 1200, 1750 and 2200. Three kinds of cavity crushing type of cavity, standard and short-end types are available for each specification respectively, which can meet the medium and fine crushing demands in different ore crushing flow of different users.

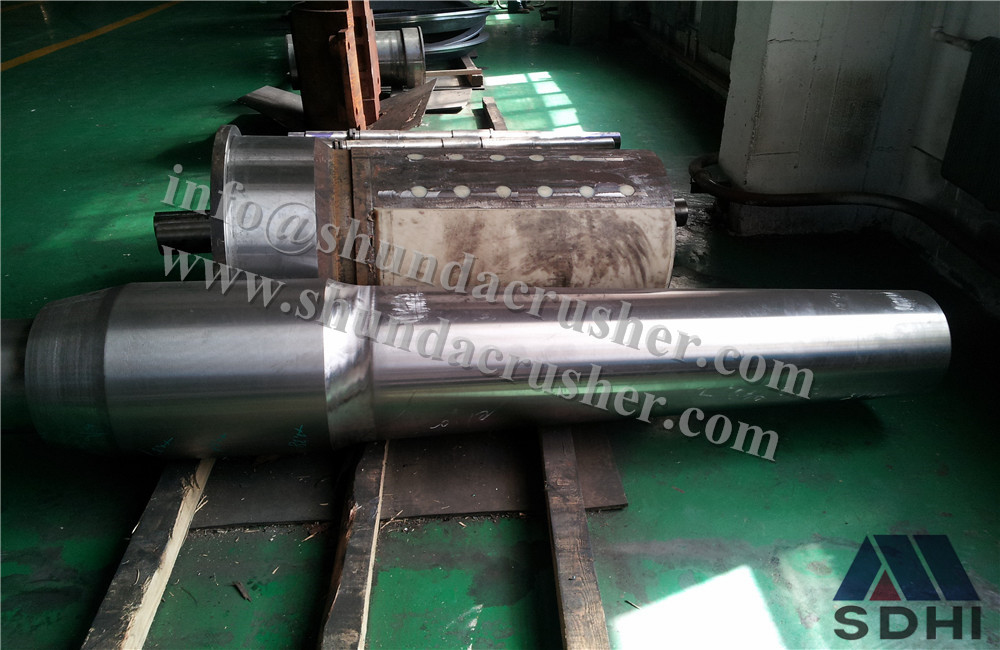

Composition of spring cone crusher:It is mainly composed of drive, supporting sleeve, adjustment cover, eccentric bushing, bowl-shaped bearing frame, breaking cone, feeding support parts, hydraulic and lubricating system and spring parts.

Operating principle of crusher:When the crusher is operated, the rotary motion of motors is transmitted to the eccentric bushing through couplers, transmission shafts and cone gears. The breaking cone parts perform the rotary motion around a fixed point under the forced movement of eccentric bushing. The crushing wall from breaking cone sometimes approaches while leaves in other times the wall surface of rolled mortar fixed on the adjustment cover to enable the ores to crush under constant impact, extrusion and bending inside the crushing cavity. The crushed ores are discharged out of the crushing cavity from ore discharging mouth relying on dead weight.