The selection of granite production line mainly based on the rock hardness and the customer's requirements of particle size, we will selectively assembly different models and equipment matching on the basis of different production scene.

Applicable materials: basalt, granite, gabbros, diabase, diorite and other hard rock materials’ thick broken, second broken and fine broken job.

Applications: water conservancy and hydropower, highways, urban construction and other industry applications. Product particle size can be combined and graded according to the different needs of users.

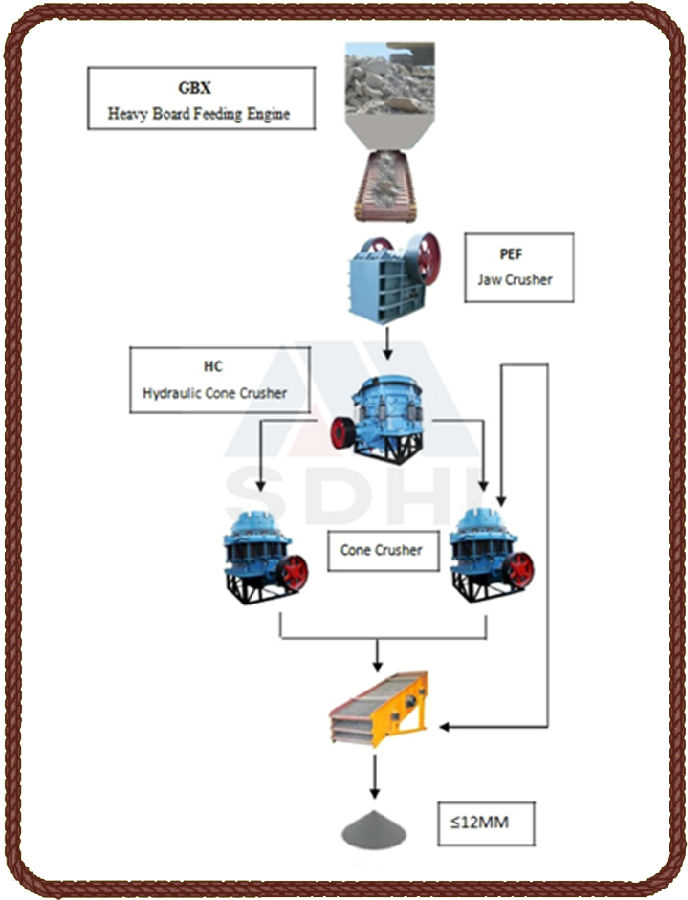

Device configuration: Board style feeding engine, jaw crusher, H series hydraulic multi-cylinder cone crusher, Xi Liansi cone crusher, vibrating screen, belt conveyor

Hard rock introduction and performance

Hard rock means the rock test specimen’s homostadial compressive strength under saturated humidity (specimen diameter is 7 ~ 250px, the height is same as diameter) greater than 29.4 × 103kPa (such as granite, diorite, basalt and other igneous rocks: irony, calcareous cemented conglomerate, sandstone, limestone, argillaceous limestone, dolomite and other sedimentary rocks; gneiss, quartzite, marble, slate rocks), abrasive to wear parts is very high. Therefore, hard rock production line design should be reasonable, not only take into account the broken items initial investment costs, but also take into account the post-operation costs.

Shunda requires a high level on the reasonable of production line. The use of the process can be achieved: high crushing efficiency, low operating cost, energy saving, uniform particle size, reduce needle rate.

Detail of granite production line: