Modle | Diameter of crushing cavity (mm) | Power(kw) | Max feed size (mm) | Rotating speed (r/min) | Capacity(t/h) | Remark | ||

Single Drive | Double Drive | Single Drive | Double Drive | |||||

PLC2100K-ST | 2195 | 250 | 200*2 | 89 | 800-1400 | 100-300 | 100-400 | ROR |

PLC2100B-ST | 2195 | 250 | 160*2 | 38 | 800-1800 | 110-245 | 120-295 | ROS |

PLC2100B-SS | 2195 | 220 | 160*2 | 51 | 800-1800 | 140-260 | 150-270 | SOS |

PLC2400K-ST | 2413 | 315 | 250*2 | 127 | 800-1300 | 100-296 | 100-490 | ROR |

PLC2400B-ST | 2413 | 315 | 250*2 | 64 | 800-1800 | 105-350 | 175-590 | ROS |

PLC2400B-SS | 2413 | 315 | 250*2 | 64 | 800-1800 | 150-350 | 215-450 | SOS |

The advantages of PLC Series Vertical Shaft Impact Crusher:

PLC Series Vertical Shaft Impact Crusher`s crushing ratio can reach above 50, the particle size of the product is good, suitable for crushing of middle and hard materials.

Under the impact of the impact, the broken material is often broken down by its most vulnerable level, this selective crushing method makes the probability of the cube shape of the particles is higher, the percentage of needle sheet can be lower than 10%

Adopt imported bearings to ensure the stable operation of the machine. And the unique Liu riveting technology, increase the strength and toughness, effectively reduce the resonance machine

Hydraulic maintenance arm, greatly reducing maintenance costs

Stone stone, hot stone and other broken way, to meet the different needs of material crushing

Double oil pump design, in normal case only one oil pump work, but only in the pressure, flow rate can not reach the set value or the first oil pump failure, the second one starts to work, to ensure the normal operation of the host

Bearing a constant temperature oil according to the oil temperature automatic cycle, to ensure that similar bearing barrel temperature and oil tank of oil temperature to prevent the winter freeze

The new impeller design, optimize the flow of material, the same power than the old type of equipment output 30%

The Production cycle of Shunda PLC Series Vertical Shaft Impact Crusher is about 65 days, but it is only for reference. Due to the impact of climate, the supply and demand of raw materials and other factors, there will be little changes in the specific production cycle, the details please get in touch with Shunda staff and subjected to the contract.

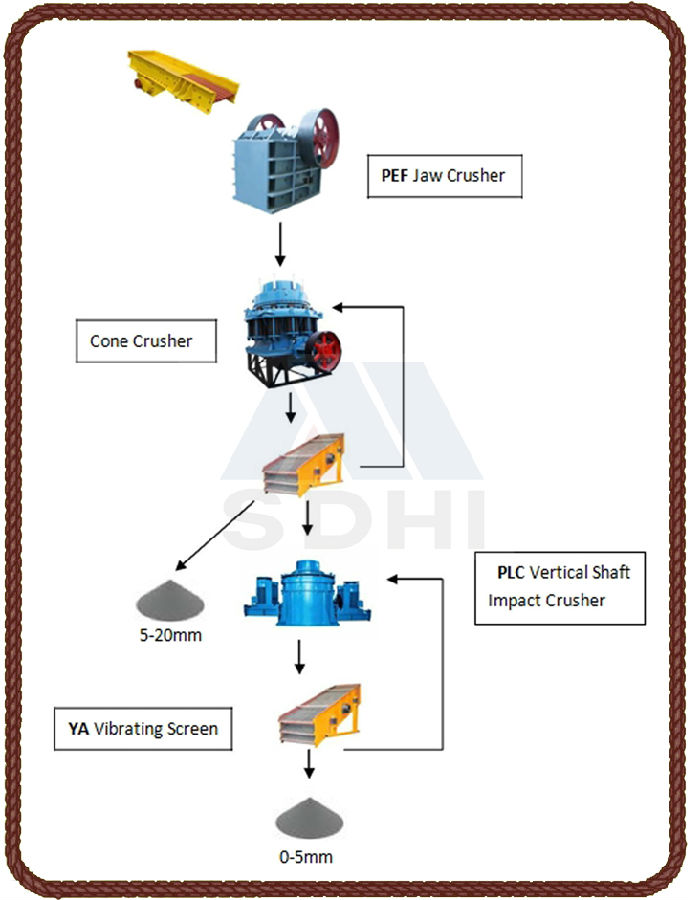

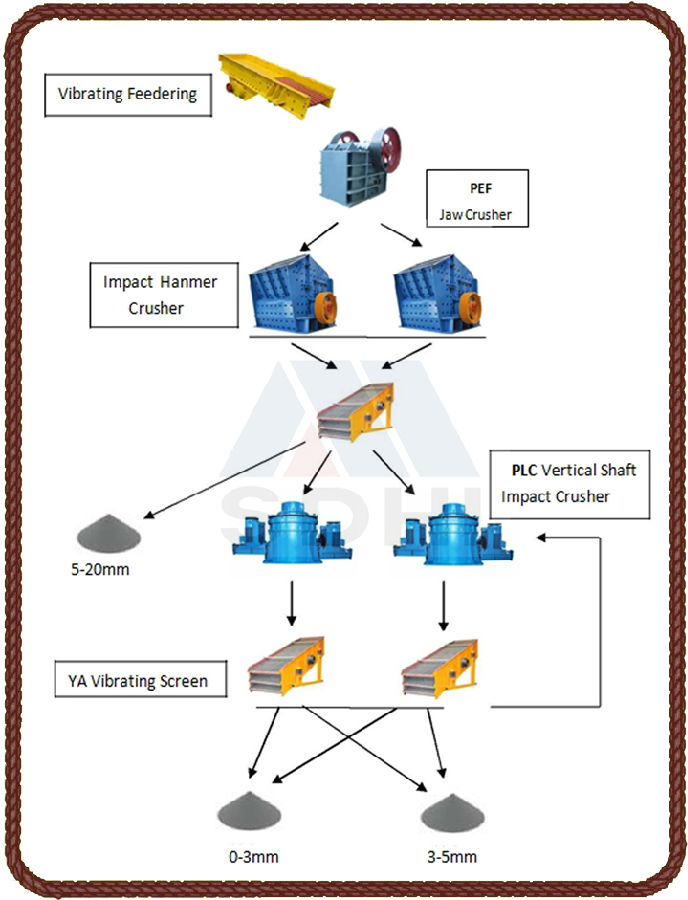

PLC Vertical Shaft Impact Crusher is a fine crusher, which adopts the methods of impacting, grinding and cutting. It is suitable for crushing and reshaping soft, medium hard and high hard ores and widely used for various ores, cement, fireproofing material, silicon carbide, bauxite chamotte, glass raw material and infrastructure construction stone, etc. The Crusher has excellent performance when used to crush silicon carbide, sintered bauxite, magnesite and other high hard and corrosion material.

Working principle:

The stone material first vertically dropped into the high-speed rotating impeller where under centrifugal force the stone impacts other stone material distributed around the impeller in form of umbrella. Then a strong whirlpool forms between the impeller and the shell. After times of impact, friction and crushing the material discharges from the discharge port to screening equipment to get required output size.

Featrues:

1. Function of fine crushing and rough grinding with high efficiency.

2. Simple structure, convenient installation and repairing; low cost of operation.

3. Good pass ability of uncrushed material; less effect by water content below 8%.

4. Good grain shape, cubic particle with less content of elongated and flaky particle; good for aggregate

shaping, manual sand making and aggregate production for road building.

5. Big bulk density; low iron pollution.

![]() PLC Series Vertical Shaft Impact Crusher.pdf

PLC Series Vertical Shaft Impact Crusher.pdf