Shunda Plant Planning

The company covers an area of 240,000m and has more than 1200 employees. Shunda products in the three stages of the upper, middle and lower reaches are all from his hand. There are R&D center, foundry, laboratory, machine shop (lathe area, grinding area, milling machine, slotting area, quality inspection area), assembly workshop, rough and spare parts warehouse, employee dormitory, employee canteen, activity center, etc. in the plant area.

FOUNDRY

WORKSHOPS OUTDOOR SCENE

WORKSHOP INDOOR SCENE

SPARE PARTS LIBRARY

As we all know, Shenyang is a well-known heavy industrial city in China. From the beginning of reform and opening-up in our country, Shenyang has become the old industrial base of the northeast. So we have the longest development history of Chinese heavy machinery industry and technical experience. Moreover, the Northeast climate in China for casting and smelting is the most appropriate. There is dry climate, good air circulation. So relative to other areas finished castings, Shunda castings have less sand holes, good density, hardwearing and high reliability. Shunda sticks strict quality control and the factory set up its own internal foundry. Our raw materials are high-quality steel from large enterprises and meticulously casted by experienced master craftsmen. From sand mould production, the casting temperature and velocity, riser position, to casting conditioning, stress relief, each step is strictly controlled according to the casting process, so we have the first-class quality assurance, which we call "Shunda Quality."

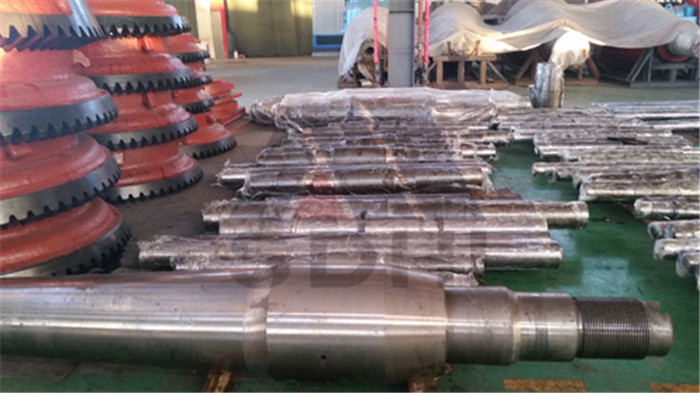

We have many machine plants and multi-purpose devices, such as lathes, grinders, millers, gear shaping machines, various types of machine tool sorted by processing steps in an orderly manner. Shunda has the largest 1.6m diameter gyratory crusher in China and 6m diameter ball mill, etc. In order to meet the production needs, we have many larger equipments and hundred-ton hanging as technology and transport support.

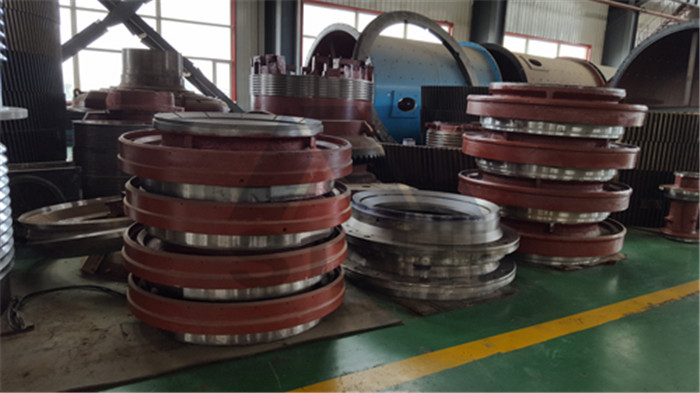

To meet the customer’s delivery time and shorten the production cycle, our spare parts shop reserves a lot of product components and wearing parts. Both in terms of customer service or sales support, we are very focused on timeliness. Shunda does things in good faith and meticulous. Each product components must be carefully checked for twice. The first time was the completion of the finished products, the second time was before loading when it ready to be shipped. Two times tests are not only the quality assurance for products and the responsible for customers, but it is also our way of survival for decades. As the Chinese saying goes " No accumulation of steps, can not lead to thousand miles. No integration of streams, can not result in seas and oceans." It is the pursuit of details made Shunda today’s achievement.

Now, Shunda rely on the old factory, builded new plant in 2008, two factory near in the way, complement each other, understanding the relative. In order to better leading the industry and get a firm foothold in the first row, the new plant is equipped with many advanced CNC production lines and sophisticated technical personnel, so the workers are experienced and staff full of virtue and talented.

The company not only to invest heavily in production costs no hesitate, but also adhere to the people-centered concept for employees to optimize their working conditions, so that the workshop air and noise environment has been significantly improved. In addition, the staff’s spare time is also colorful and the employee give their staff meticulous care. Thus, Shunda people not only is proud and happy, so is satisfied and impassioned. When you first step into Shunda, you will be deeply infected by Shunda corporate culture and become addicted to it.

Do you want to try? We are waiting for you.